SIMATIC Safety Integrated – Seamless Machine Safety

Save on hardware and engineering and achieve the perfect match between safety and machine design thanks to the integrated safety functions.

Implementing safety of machinery is time-consuming and requires specific expertise in safety regulations and legislation. To overcome the lack of know-how and to limit the time and effort spent designing safety functions, safety concepts are often inherited from older machine designs. However, these inherited safety concepts might be insufficient for the specific machine requirements or could reduce machine availability.

Reusing outdated safety concepts from previous machines could lead to non-compliance with standards and regulations, low machine productivity, as well as accidents and legal consequences.

On the other hand, manually designing individual safety concepts for each machine might be time-consuming and lead to increased maintenance efforts, as many different safety concepts need to be maintained.

Finding the optimal solution to this dilemma is not easy. A continuous workflow that guides through the necessary steps towards a safe machine design would be beneficial.

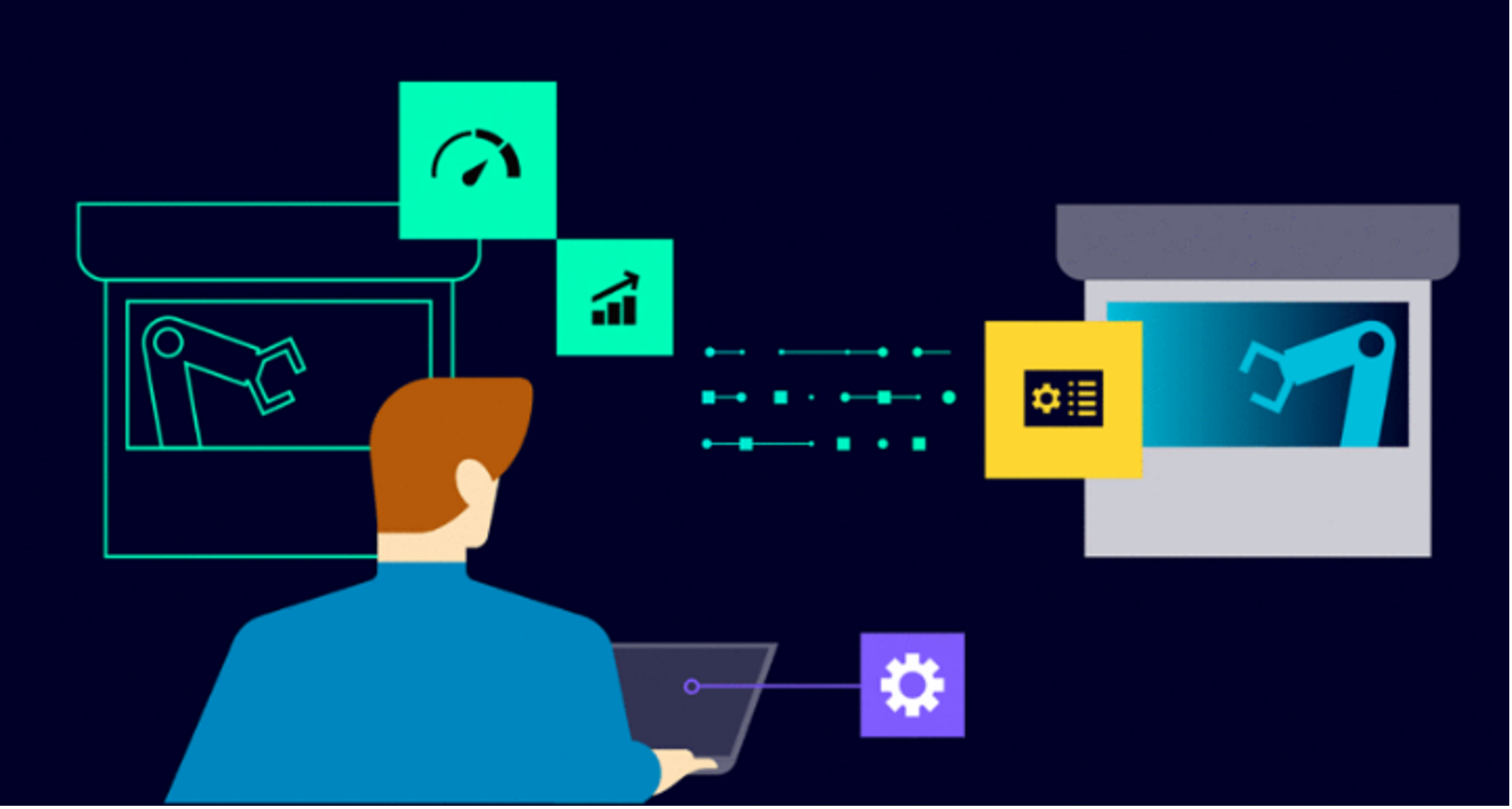

This is exactly where the digital workflow for machine safety from Siemens comes in. With a linked toolchain from risk assessment, safety evaluation, hardware selection up to engineering and validation, Siemens provides tooling that gives you peace of mind. This allows you to reduce your efforts for documentation, reliability calculation, and validation to a minimum.

Additionally, Siemens offers suitable components ranging from basic machine safety to fully flexible controller or drive-based safety solutions:

Software-less Machine Safety

The software-less machine safety includes basic safety implementation without extensive programming for non-complex environments. It is designed for the engineering of simple safety functions according to the safety requirements derived from the risk assessment. SIRIUS 3SK1 safety relays offer low-cost and flexible safety implementation through integrated DIP-switches for device parameterization without extensive safety programming. Thus, basic safety functions can be implemented without the need for highly qualified safety programming specialists. The complementary portfolio of SIRIUS Command, Control, and Hybrid devices allows for end-to-end, scalable, and certified safety solutions with seamless integration into the SIMATIC automation system. Supported by ready-to-use application examples, the entire safety process for basic safety measures, including implementation, documentation, validation, and certification, is very simple and time-efficient.

Flexible Machine Safety

Flexibility in production processes also requires flexibility in the safety concept to ensure optimal productivity. Siemens offers a broad product portfolio (SIRIUS, SIMATIC, SINAMICS) with scalable safety solutions that can be easily adapted, modified, or expanded. Customers can define their own approach to perfectly fit their applications and functional safety requirements.

The portfolio is scalable with respect to the number and type of safety functions required for an application. Safety functions can be tailored to exact needs using intelligent product configurators, combined with best-in-class engineering tools in the TIA Portal and simulation tools like SIRIUS SIM and SIMIT.