Top 5 Challenges Integrators Have Using Siemens (And How to Overcome Them)

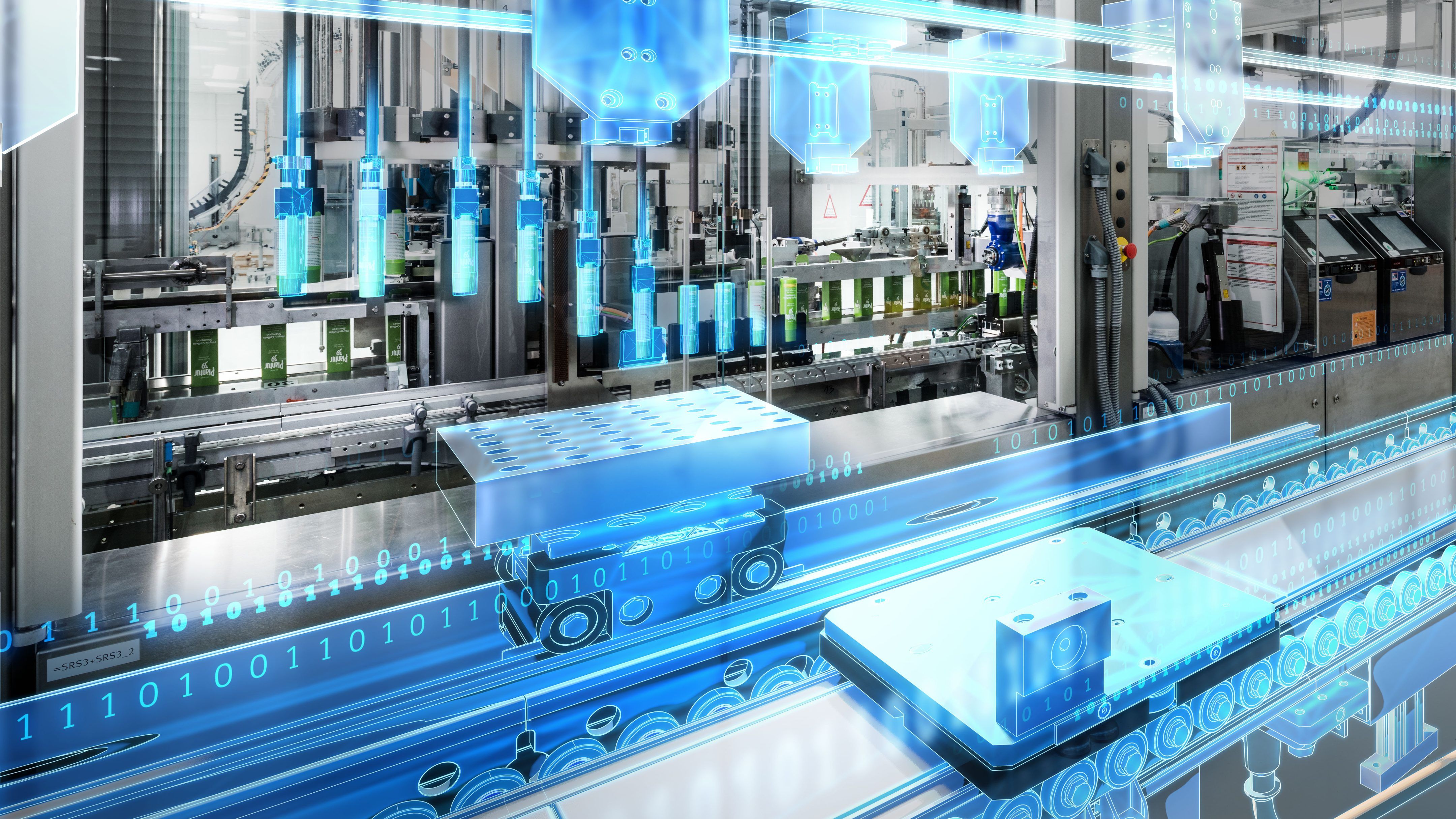

Siemens automation and control systems are a staple in modern manufacturing environments for a reason. Recognized globally for their robust hardware, advanced software, and total cost of ownership benefits, Siemens platforms have earned their place across industries such as automotive, food & beverage, pharmaceuticals and more. Still, even the most experienced systems integrators can encounter roadblocks when implementing Siemens solutions, especially those new to the ecosystem or shifting from a different controls platform.

Why Choose Siemens?

Before diving into the challenges, it’s worth noting why integrators opt for Siemens in the first place. The brand is globally trusted and known for high-quality hardware and software. Integrators often find that Siemens systems reduce total cost of ownership over the long term by enhancing reliability, streamlining installation, and minimizing maintenance needs. In industries that demand precision and uptime, that level of assurance is critical.

Challenge #1: Lack of Familiarity Compared to Rockwell and Others

The Issue:

One of the most common hurdles integrators face is the learning curve that comes with transitioning to Siemens from other platforms like Rockwell. While Siemens adheres to IEC 61131-3 programming standards and supports modern industrial protocols like OPC UA and IO-Link, integrators unfamiliar with these tools may feel uncertain at the outset. This typically surfaces in the early project stages (controls design and software design) where foundational decisions are made.

Why It Matters:

Without a clear path forward, projects can be delayed while higher-level engineers are brought in to chart the course, leading to increased costs and missed deadlines.

Who It Affects:

Smaller integrators or teams less exposed to Siemens technology are most impacted, particularly those with limited engineering resources or legacy mindsets stemming from past Siemens systems from the ’80s and ’90s.

How to Overcome It:

Experienced integrators partner with Siemens' local sales and technical teams right from the RFQ stage. This proactive planning ensures the right hardware and software are selected early, reducing rework later. Testing demo units, engaging with experts, and attending Siemens workshops also accelerate learning and confidence-building.

Challenge #2: Product Selection Uncertainty

The Issue:

Knowing which Siemens products (such as S7 PLCs, HMI panels, or drives) to choose for a given application can be daunting. Choosing the wrong product upfront can result in compatibility issues or performance gaps, adding time and cost to already tight project schedules.

The Solution:

Distributors like GCG play a key role here, offering expert guidance and fast access to demo units and selection tools. By involving a knowledgeable distributor early, integrators avoid common missteps and ensure technology choices align with project needs.

Challenge #3: Legacy Bias from Earlier Siemens Generations

The Issue:

Many engineers and managers remember Siemens systems from decades ago, which were known for being less intuitive in North American environments. Those early experiences influence today’s adoption decisions, even though Siemens has since evolved dramatically in terms of usability, integration, and standards compliance.

The Fix:

The Fix:

Today's Siemens ecosystem is nothing like its legacy predecessor. Updates like TIA Portal, multi-user engineering, scalable PLCs (e.g., the new S7-1200-G2), and seamless integration with SCADA and third-party systems have removed many of the past pain points. It’s all about re-educating teams and offering hands-on experience with current technology to dispel outdated perceptions.

Challenge #4: Integration with Diverse Machine Architectures

The Issue:

In facilities with varied machine brands and control systems, integration becomes complex—especially when data must flow between Siemens and non-Siemens devices. Without standard interoperability, integrators may face additional coding, protocol translation, or hardware adjustments.

What Works:

Siemens’ embrace of open standards—such as OPC UA, IO-Link, and Profinet—makes cross-platform integration significantly easier. Their newer platforms, including Industrial Edge devices, are built with these scenarios in mind, enabling flexibility without compromising system reliability.

Challenge #5: Scaling Technical Support and Resources

The Issue:

As project complexity grows, so does the need for specialized support. Without a solid network, integrators can feel isolated. Missed deadlines, overworked teams, and stalled troubleshooting sessions are all potential fallout.

Solution:

This is where distributor partners like GCG prove invaluable. With a network of technical experts, on-call support, and robust training programs, GCG provides the infrastructure integrators need to scale confidently. From fast quoting to post-installation troubleshooting, GCG keeps the process moving efficiently.

Looking Ahead: How Siemens Is Reducing Integration Pain

Today’s Siemens ecosystem is built with flexibility and integration in mind. The latest innovations, such as TIA Portal enhancements, cloud-based analytics, edge computing, and next-gen PLCs, are transforming how integrators deploy automation. These tools are faster to configure, easier to scale, and better at communicating across diverse systems.

To stay ahead, integrators are encouraged to conduct a Needs Assessment early in the planning process and align with trusted partners for both technology guidance and implementation support.

Final Thought: It’s a Team Effort

Integrating Siemens isn’t a solo endeavor—it’s a partnership between integrator, distributor, and OEM. Challenges will always exist in complex automation environments, but the key lies in proactive planning, education, and collaboration.

By engaging early with Siemens experts and trusted distributors like GCG, integrators can avoid common pitfalls, fast-track their learning curve, and deliver more successful outcomes for their clients.

Need help planning your next Siemens integration?

I would love to help you get started. Let's connect to discuss how we can help you execute your next project with confidence.

Visit us at the WITS show in Wichita:

If you’re attending the WITS show this October, be sure to stop by our booth to see Siemens solutions in action. Our team will be showcasing the latest in automation, control, and integration technology. It’s the perfect opportunity to get hands-on experience, ask questions, and explore how Siemens can help you tackle your toughest integration challenges.